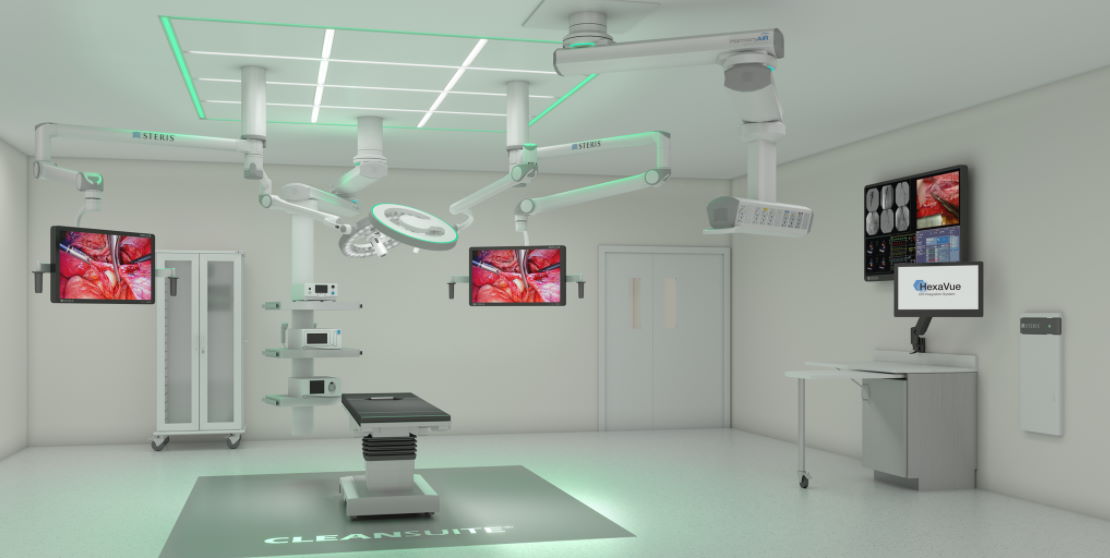

CLEANSUITE® Operating Room

Ceiling System

- Helps mitigate the risk of airborne particles

- OR air quality that surpasses traditional site-built, laminar-flow ceiling systems that conform to US FED STD 209E CLASS 100,000/ISO8, CLEANSUITE air quality surpasses this standard for operating rooms by 1000X

- Prefabricated structural frame installs six times faster and up to 40% less cost than traditional laminar-flow ceiling systems built onsite

- Enables precise placement of ceiling-mounted surgical equipment (lights, booms, monitors, c-arms) to create a complete ceiling solution for hospitals

ULTRA CLEAN, ULTRA VALUE

With CLEANSUITE, a single large-diffuser system delivers true gapless laminar flow to minimize turbulence and gently guide particles away from the surgical site. High-performance diffuser grilles provide unidirectional flow and are engineered to pharmaceutical and cleanroom specifications. While typical particle counts in an OR are 100,000 particles/ft3, CLEANSUITE standard is 100 particles/ft3, providing a solution that achieves the ISO Class 5 cleanroom specification, going beyond the industry standard for patient safety. CLEANSUITE directs airborne particles and contaminants away from the patient and Operating Room (OR) staff, while encompassing the room in HEPA-filtered air.

PREFABRICATED OPERATING ROOM CEILING SYSTEM

Because of its modular system delivered as a whole, CLEANSUITE is six times faster to install and up to 40% less cost than traditional laminar-flow ceiling systems built on-site. Its structural steel frame fits tight spaces and tight timeframes.

- Simplified connections eliminate the need for on-site welding and also minimize labor for Heating, Ventilation and Air Conditioning (HVAC), medical gases, and utilities

- Internal and external truss systems allow for seamless mounting of surgical lights, booms, monitors, and C-arms

- Compatible with all ceiling-mounted OR equipment - not just equipment manufactured by STERIS

FUTURE-READY FOR THE MODERN OPERATING ROOM

Designed to be an Operating Room ceiling system that grows with your needs, CLEANSUITE's grid modularity makes future OR renovations simpler and less costly. Easily move or add equipment around the cleanroom ceiling grid without excessive OR downtime.

As your partner in the OR, STERIS supports your project design and implementation. Over nearly six decades, our project design management group has completed more than 20,000 projects and team members have an average of 25 years of experience in hospital/healthcare facility planning and design.

How is CLEANSUITE more economical than traditional laminar-flow ceiling systems?

Traditional laminar-flow ceiling systems are built on-site. Because CLEANSUITE is a prefabricated modular system, it's delivered as a whole. Its structural steel frame fits through a standard 36" doorway, and simplified connections eliminate the need for on-site welding and labor for HVAC, medical gases, and utilities.

How does CLEANSUITE support infection prevention efforts?

There are numerous ways that pathogens may contaminate the surgical field. Contamination sources in the Operating Room may include equipment, instruments, the surgical team, OR traffic, and air quality. Published clinical studies and professional organizations such as Association of periOperative Registered Nurses (AORN) agree that airborne squames, or skin scale particles, shed from the patient and personnel in the operating room are the primary source of bacteria that cause infections in the surgical suite.1,2

CLEANSUITE features air quality that surpasses current standards for Operating Rooms by 1000x. At 100 particles/ft3, CLEANSUITE is a solution that achieves the ISO Class 5 cleanroom specification.

Is CLEANSUITE only compatible with STERIS equipment?

CLEANSUITE is compatible with all ceiling-mounted OR equipment - not just equipment manufactured by STERIS.

1 Woods, J. E., Braymen, D. T. Rasmussen, R. W., Reynolds, P. E., Montag, G. M. (1986). Ventilation requirements in hospital operating rooms - Part I: Cont of airborne particles. ASHRAE Transactions 92(2).

2 Knobben, B. A., Van Horn, J. R., Van Der Mei H. C., Brusscher, H. J. (2006). Evaluation of measures to decrease intra-operative bacterial contamination in orthopedic implant surgery. Journal Hospital Infection. 62, 174-80. Retrieved from Clean Air in the Operating Room

Laminar flow air delivery in the Operating Room

Improve Air Purity in the OR

Prefabricated Modular Ceiling Solution for the Operating Room

AUTOCAD BLOCKS

REVIT FAMILY OBJECTS

EQUIPMENT DRAWINGS

BROCHURES

![]() CLEANSUITE CEILING SYSTEM BROCHURE

CLEANSUITE CEILING SYSTEM BROCHURE

Can't find what you are looking for?